Floor Adhesives & Related Products

A variety of wood flooring and adhesives is available. Waterproof PVA glues, Sika adhesives and bonding kits for wooden planks and boards. Find all accessories needed to glue your floor directly to the sub-floor. With our products, you have guaranteed extra strength combined with flexibility for glueing your floor joints.

Wood Flooring Glues & Adhesives

-

WATERPROOF WOOD GLUE - Adhesive - 500ml

All-purpose wood glue which has a good resistance to moisture and gives great bonding. It dries clear and doesn't stain. The adhesive is water-based for safe use and clean-up afterwards.

Packaging / Weight: 500ml

Coverage Per Box: 10M2

-

WATERPROOF WOOD GLUE - Adhesive - 1 Litre

All-purpose wood glue which has a good resistance to moisture and gives great bonding. It dries clear and doesn't stain. The adhesive is water-based for safe use and clean-up afterwards.

Packaging / Weight: 1 Litre

Coverage Per Box: 20M2

-

STAUF - Wood Flooring Adhesive SMP930 18kg

Wood Flooring Adhesive - perfect for solid wood, engineered planks & herringbone.

STAUF SMP 930 - 1 component hard elastic SMP wood flooring adhesive.

Packaging / Weight: 18kg

Coverage Per Box: 18M2

Product Features:

- hard elastic, tension-reducing parquet bonding

- can be applied to almost all substrate without primers

- excess adhesive easy to remove

- water and solvent-free

- no wood swelling

- aging-resistant

- elastically deformable

- suitable on subfloor heating systems

- not sensitive to frost

- very good thread formation

- fast setting

- beige colour

Suitable For:

- vertical finger parquet lamellas

- solid planks, with relation width/thickness max. 7:1

- multiple layer wood flooring

- mosaic parquet

- wood strip flooring raw

Prior to processing, the subfloor must be checked according to the standard DIN 18356 or corresponding national standards. The subfloor shall be resistant to pressure and tension, free of cracks, must have sufficient surface strength, be permanently dry, level, clean and free of from contaminants that may prevent adhesion, sinter layers etc. In addition, porosity and grip of surface need to be checked. Also check moisture content and absorption of subfloors as well as temperature, air humidity and subfloor temperature.

It must be ensured that the subfloor is ready for installation by performing proper subfloor preparation, floors must be clean, have sufficient surface strength, must be level, permanently dry and free of cracks. A mechanical pretreatment of the subfloor (sweeping, vacuuming, mechanical brushing, sanding, milling, shot blasting) must be performed depending on type and condition of subfloor. Cracks and joints, except expansion joints and other construction joints, shall be solidly closed with STAUF repair resin and floor brackets. Cavities and indentations can be filled with a non self-levelling STAUF levelling compound. If necessary, make sure subfloors are level, have sufficient absorptive capacity and grip by applying the appropriate STAUF levelling compound.

Apply adhesive to sub floor using the appropriate STAUF notched trowel, avoid adhesive pooling and excessive layer thickness by evenly raking the notched trowel over adhesive layer. Install wood flooring during specified open time, slide in and press down firmly. In particular with raw wood flooring, avoided pushing adhesive into joints. Adhesive in joints can impair subsequent surface treatment. Depending on the degree of setting, adhesive residues can be removed with the appropriate STAUF cleaners. Please test the effect of the cleaner on the finish of the wood flooring in an inconspicuous area or on a sample prior to applying the cleaner. Hardened adhesive residues can easily be removed mechanically, mostly residuefree. However, longer exposures on finished wood flooring should be avoided to prevent possible contouring.

The adhesive hardens when reacting with moisture either in the form of air humidity, wood or substrate moisture. The higher the ambient temperature, the faster the adhesive sets. Setting time increases with thickness of the adhesive layer. Plasticizers contained in the adhesive can cause flow asphalts to partially dissolve and may affect the wood flooring finish systems, especially for wood flooring installed without tongue and groove technique. For solid floorboards and solid parquet flooring from a width thickness ratio of 1:7, for thinner solid wood formats of 1:5 (e g. 10 mm lamparquet), or for laying strongly reacting solid wood types on underfloor heating, it can be useful to bond them in a shear-resistant or hard manner.

-

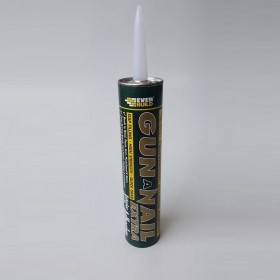

Gun A Nail

Gun A Nail Standard, is a high strength, gap filling multi-purpose building adhesive based on a tackified solvent free system for use in a wide variety of building and home improvement applications.

Gun A Nail Standard can be used where at least one of the substrates to be bonded is porous.

Do not apply Gun A Nail Standard at temperatures below +4°C. Application Temp. Range +4°C to +40°C

-

Mitre Fast Bonding Adhesive Kit

Mitre Fast Bonding Kit is a two part instant adhesive system comprising a cyanoacrylate adhesive and aerosol activator. Mitre Fast is mainly used in the furniture, timber, kitchen and plastics industries where its instant bonding properties dramatically reduce assembly times for mitre joints when compared to conventional wood adhesives. Also suitable for bonding of MDF, rubber, PVCu, metals etc.

-

WEB TACK - Bulk Tank 17kg Clear

Web Tack is a fast drying spray adhesive, suitable for permanently bonding a wide variety of substrates including wood, metals, rubber, most plastics, cardboard, polythene and concrete, as well as decorative laminates. It also provides good temperature resistance

Coverage: 128m2 for a 17kg canister

Directions:

- Ensure all surfaces are clean, sound, dry and free from dust, grease or other contaminants

- Connect the hose to the canister and the spray gun to the hose and tighten the connections

- Open the valve on the canister, the valve should remain open until the canister is used up

- The hose and gun should remain connected until the canister is used

- Hold the spray gun 30-35cm away at 90° to the surface and apply an even coat of adhesive to both substrates, ensuring 80-100%coverage and spraying one surface vertically and the other horizontally

- Pay particular attention to the edges. When the adhesive is dry to the touch (1-2 minutes dependent on substrates and temperature), and does not transfer, it is ready for bonding

- Bring the two surfaces together and apply a uniform pressure, starting in the middle and working out, pay particular attention to the edges

- Full cure in 24 hours

- Avoid over spraying and pooling of the adhesive as this will increase the drying time and may cause adhesive to show through the laminate

Download Brochure

-

WEB TACK - Aerosol 500ml

Web Tack is a fast drying spray adhesive, suitable for permanently bonding a wide variety of substrates including wood, metals, rubber, most plastics, cardboard, polythene and concrete, as well as decorative laminates. It also provides good temperature resistance

Download Brochure

-

WEB TACK - Tack Gun

Web Tack is a fast drying spray adhesive, suitable for permanently bonding a wide variety of substrates including wood, metals, rubber, most plastics, cardboard, polythene and concrete, as well as decorative laminates. It also provides good temperature resistance

Directions:

- Ensure all surfaces are clean, sound, dry and free from dust, grease or other contaminants

- Connect the hose to the canister and the spray gun to the hose and tighten the connections

- Open the valve on the canister, the valve should remain open until the canister is used up

- The hose and gun should remain connected until the canister is used

- Hold the spray gun 30-35cm away at 90° to the surface and apply an even coat of adhesive to both substrates, ensuring 80-100%coverage and spraying one surface vertically and the other horizontally

- Pay particular attention to the edges. When the adhesive is dry to the touch (1-2 minutes dependent on substrates and temperature), and does not transfer, it is ready for bonding

- Bring the two surfaces together and apply a uniform pressure, starting in the middle and working out, pay particular attention to the edges

- Full cure in 24 hours

- Avoid over spraying and pooling of the adhesive as this will increase the drying time and may cause adhesive to show through the laminate

Download Brochure

-

WEB TACK - Hose 3.66m

Web Tack is a fast drying spray adhesive, suitable for permanently bonding a wide variety of substrates including wood, metals, rubber, most plastics, cardboard, polythene and concrete, as well as decorative laminates. It also provides good temperature resistance

Directions:

- Ensure all surfaces are clean, sound, dry and free from dust, grease or other contaminants

- Connect the hose to the canister and the spray gun to the hose and tighten the connections

- Open the valve on the canister, the valve should remain open until the canister is used up

- The hose and gun should remain connected until the canister is used

- Hold the spray gun 30-35cm away at 90° to the surface and apply an even coat of adhesive to both substrates, ensuring 80-100%coverage and spraying one surface vertically and the other horizontally

- Pay particular attention to the edges. When the adhesive is dry to the touch (1-2 minutes dependent on substrates and temperature), and does not transfer, it is ready for bonding

- Bring the two surfaces together and apply a uniform pressure, starting in the middle and working out, pay particular attention to the edges

- Full cure in 24 hours

- Avoid over spraying and pooling of the adhesive as this will increase the drying time and may cause adhesive to show through the laminate

Download Brochure

Floor Adhesives & Glues

Our adhesives are characterised by excellent elasticity and spreadability. These glues have exceptional quality and a high level of resistance to water and heat. You need only a thin layer to ensure that the glue is working properly. When you pick your hardwood flooring you don't need to worry about a vapour barrier as glue works as one already.